Quality Control

QUALITY MATTERS!

QUALITY MATTERS!

We are committed to providing the highest level of quality brass products as possible. That's why we've invested heavily in our quality control processes and equipment.

Our quality control department is moving the fitting industry forward, by utilizing next generation, automated optical technology. We now have the ability to perform hundreds of high precision measurements in seconds while automatically recording data and generating inspection reports.

WHAT'S IN YOUR BRASS?

WHAT'S IN YOUR BRASS?

Knowing the material composition of your brass products is important. Most brass suppliers use material certificates from the brass mills to certify the chemical composition of their products.

At Robo-Fit, we embrace the mantra of “trust but verify.”

X-ray fluorescence involves sophisticated physics, this process can be summarized as (i) X-rays out, (ii) X-rays back, (iii) fancy math (iv) answer. The instrument can be used to determine the composition of nearly any type of sample.

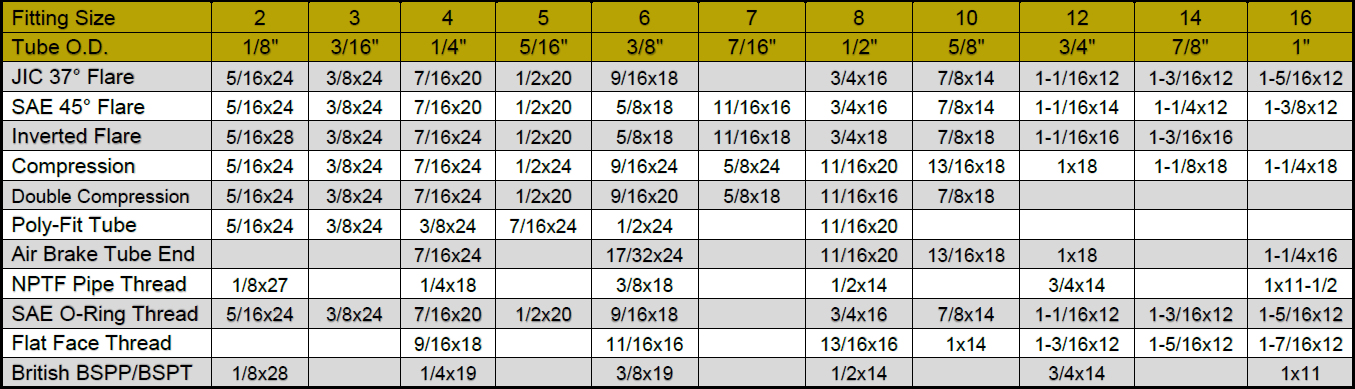

THREAD REFERENCE CHART

THREAD REFERENCE CHART

24 HOUR COPPER PRICES

24 HOUR COPPER PRICES

![[Most Recent Quotes from www.kitco.com]](http://www.kitconet.com/charts/metals/base/copper-d.gif) |

US Dollars

US Dollars

Mexican Peso

Mexican Peso